-

info@cldhiman.com -

View Mobile Number - Send SMS

- Send Email

- GST No. 09AKXPD0052E1ZA

Pre Cleaning Equipment

Leading Manufacturers, Exporters, Wholesaler, Retailer of Destoner Machine, Gyro Screen, Inline Vibro Feeder, Magnetic Separator, Plan Shifter and Vibro Separator from Saharanpur.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Automatic |

| Certification | CE Certified |

| Application | Removing Soil Stone |

| Weight | 100-200kg |

| Voltage | 220V |

| Power | 1-3kw |

| Driven Type | Electric |

| Warranty | 1 Year |

Preferred Buyer From

| Location | Anywhere in India |

Our company has conquered great heights in the field of De Stoner supply and export. The De Stoner is suitable for handling all cereals, pulses, legumes, some species and industrial materials such as; plastics, chemicals and minerals. The product should be dry, granular and of reasonable particle size.

Construction :

The De Stoner consists of :

- A trapezoidal working table, which is fully covered.

- Woven wire mesh bed material (sized to suit product and changeablea.

- Robust supporting structure, with anti vibratory mounts.

- It has an air lock device on grain intake.

- Good grain discharge outlet (sa with sleeve(sa.

- The machine has a Stone outlet with sleeve.

- The drive consisting of one or two vibratory motor(sa mounted to robust frame below table.

Advantages :

- The De stoner has smooth and silent operation.

- Drive by electric vibratory motor for negligible maintenance. It has high capacity due to compact body size and low power consumption. Dust free operation

- Totally enclosed top connected to fan

Features :

- Suitable for wide variety of products

- Capacities from 750 kg to 8 TPH

- Easy to clean and minimum maintenance

- Remove stones accurately and reliably

- Simple and fine adjustment for optimum performance

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Automatic |

| Certification | CE Certified |

| Voltage | 220V |

| Gross Power | 1-5kw |

| Driven Type | Electric |

| Warranty | 1 Year |

Preferred Buyer From

| Location | Anywhere in India |

Gyro Screen is the circular screens operating with special Vibratory Motor imparting vibration in multiple directions to the screen assembly. Gyratory motion is the most effective method for screening, complete machine consists of Vibration generating base which houses the Vibratory Motor and Screening Assembly with wire mesh or perforated sheet. The material fed on the screen travels above the screen or passes through the screen depending upon its particle size and nature. "CLDS " gyro screen provides optimum screening & assures maximum feed-rate & efficiency.

CLDS Gyro screen use in solid-solid, solid-liquid separation in different type of industries.

Applications :

- Plastic and Polymer

- Minerals

- Metals

- Pharmaceuticals

- Herbal

- Chemical

- Agro

- Paper and Pulp

- Engineering

- Spices

- Refractories

- Abrasives

- Ceramic

- Starch

- Glucose

- Dairy Industry

- Pesticides

- Insecticides

- Soap and Detergent

Model :

“CLDS ”Gyro screen are available in M.S., SS304, SS316, & SS316L. Machine non contact parts are in M.S. Machine motors are manufacture by us. Motor power supply is 3 Ph. 440 V 50 Hz.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Inline |

| Certification | CE Certified |

| Voltage | 220V |

| Power | 1-3kw |

| Driven Type | Electric |

| Warranty | 1 Year |

Preferred Buyer From

| Location | Anywhere in India |

CLDS Inline Vibro Screen also known as “Flo-Thru” Low-Profile Vibro screen. Inline vibro screen employ two vibratory motors mounted on opposing exterior sidewalls of the unit, reducing minimum height requirements significantly. This CLDS inline vibro screen innovation also enables the bottom outlet to be located directly below the top inlet, allowing material to fall vertically through the screen at high rates. The low profile separator has a single vertically mounted motor to generate a sifting motion across the screen plane. The Inline Low Profile vibro screen offers high capacities of wet or dry scalping in a low headroom design. Available from 24" to 48" in diameter. This range of separators perfect for all processing industries and application like prepacking screening, bulk bag unloading and screening of raw ingredients.

Features :

- Less plant area with higher outputs.

- Motor force for maximizing screening efficiency and capacity.

- Hassle-free cleaning and maintenance in place without disassembly.

- Adjustable motor mounting angle.

- Lesser manpower as easy to operate.

- Low installation cost.

- Personalised inlets and outlets.

Applications :

- High temperature applications.

- High capacity scalping applications.

- pre-packing screening applications.

- Batch processes plant applications.

- Installation above Storage tank / blenders / mixers.

- Safety screening for final products.

- Accommodated into existing production lines.

Model :

“CLDS ” Inline vibro screen are available in M.S., SS304, SS316, & SS316L. Machine non contact parts are in M.S. Machine motors are manufacture by us. Motor power supply is 3 Ph. 440 V 50 Hz.

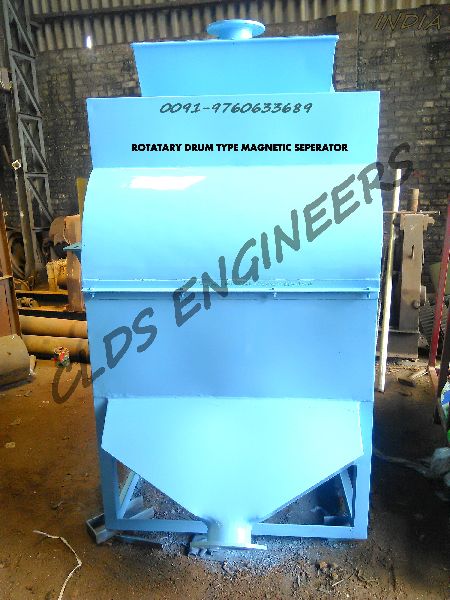

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Automatic |

| Certification | CE Certified |

| Weight | 100-200kg |

| Voltage | 220V |

| Power | 1-3kw |

| Warranty | 1 Year |

| Capacity | 0.5TPH to 5 TPH |

Preferred Buyer From

| Location | Anywhere in India |

CLDS Permanent Drum type Magnetic Separator is most useful for separating tramp iron from non magnetic material processed in bulk quantity, for the purity of end products, recovery of metal having commercial value and protection of processing plant and machinery.

Magnetic Separators are available for installation in the Feed lines such as at the outlet of separation machine, grinding machine, mixture, elevator, screw conveyor etc. The Magnetic Drum incorporates High Intensity stroncium / Rare Earth Magnets. Flanged type Inlet and outlet connections are provided.

Features :

- Drum consists of permanent magnets.

- Strong & heavy construction.

- Automatic separation of iron particles.

- Enclosed design to avoid dusting and pollution.

Industry :

CLDS Magnetic separator used in different type of industries. These are widely used for Cattle Feed Plants, Flour Mills, Rice Mill, Minerals, Refractory, Glass and many other Products.

- Food Industry.

- Agro products.

- Chemical industry.

- Pharmaceuticals.

- Minerals Industries

- Ceramics Industries

- Spices, Paper, Sugar Industries

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Automatic |

| Certification | CE Certified |

| Application | Separating Granules |

| Voltage | 220V |

| Power | 1-3kw |

| Driven Type | Electric |

| Warranty | 1 Year |

Preferred Buyer From

| Location | Anywhere in India |

Scope of Plan Sifters

The square sifter offers many advantages for sifting processes at high capacities. It provides large sifting area in very limited space. The maximum sifting area can be obtained by using different types of boxes. It is used to classify the broken and floury products and classify different kinds of grains.

Applications

- At Food Industry

- Wheat, rye, oats, barley and corn processing plants.

- Coffee and similar products processing plants.

- And other food products processing plants

Structure of Plan Sifters

This machine consists of three main parts. Two sieve boxes and a central framework containing the drive unit. These parts are assembled by means ofscrews and transversal beams.

It is possible to separate the machine into three main parts for an easy make handling, shipping and hoisting to the installation floor.

- 2 pieces symmetrically designed sieve boxes.

- 1 piece drive housing

- 2 pieces carrier arms

- 1 set of suspension group including suspension rods

The inner framework comprises all the parts dealing with the machine motion, in particular, the electrical motor, shaft and the counterweight mass. The whole shaft - counterweight unit is bedded by double ball bearings. The drive unit is easily accessible by removing the large side panels covering the central framework.

Working Principal of Plan Sifters

The product comes from above through one or two inlets and is sifted in the sieve nest, this operation being due to rotary motion of the machine and gravity. In this way from 5 (five) to 7 (seven) selections (sorts of product) with different granules can be obtained at the horizontally divided passages and 12 (twelve) selections at the vertically divided passages. A special device fitted at the inlet of channels provides a very precise separation of the product load along the entire width of the upper sieves for a remarkable increasing of the sifting of the single passage. The great numbers of superimposed sieves and their square shape also guarantee an effective sifting action and a precise classification of the products, positively affecting the final grinding yield. Each machine is completed with its own product inlet and outlet boards, the discharge control spouts and the connection sleeves made of fabric permeable to the air. The machine is easy in maintenance for it's quite an easy matter to install and dismantle and insert the telero frames into the boxes. The special and even structures of sifters do not allow insects and moths to shelter.

Featrues :

- High sifting capacity can be obtained by using different frame heights and intermediate frames aspacers). In this way, below and above sifting paths can be adjusted.

- Effective sifting possibility at high capacities. It is possible to increase 22 % sifting area by using “G” type sifter boxes Each sifting cabin can accommodate up to 28 sifters.

- A special pressure-clamping device provides proper and tight closing of access doors, Two-way product flow.

- The sieves, square shaped and having an unchangeable structure, are made of first quality stable wood and are completely covered with laminated plastic aFormica).

- More sifting area is provided by changing the sieve frames position in right angle.

- Vertical and horizontal dividing possibility of sifting passages at any required level.

- Easy cleaning and maintenance possibility.

- Internally coated insulation panels to avoid condensation, if necessary.

- A large variety of standard and special sieves enable the arrangement of many sifting in order to meet any flow sheet demand.

Types of Plan Sifters

- Square plansifter with 4 sections and superimposed max. 12 sifter frames per section.

- Square plansifter with 4 sections and superimposed max. 16 sifter frames per section.

- Square plansifter with 8 sections and superimposed max. 16 sifter frames per section.

- Square plansifter with 8 sections and superimposed max. 16 sifter frames per section.

- Square plansifter with 8 sections and superimposed max. 24 sifter frames per section.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Automatic |

| Material | Stainless Steel |

| Certification | CE Certified |

| Voltage | 220V |

| Capacity | 500-1000L |

| Warranty | 1 Year |

Preferred Buyer From

| Location | Anywhere in India |